Client: E&E Solutions Inc, JBIC

Survey of laws and regulations on environmental and social impact assessment in Vietnam (Hanoi, Hai Phong, Thanh Hoa, Binh Thuan)

Client: E&E Solutions Inc, JBIC

Survey of laws and regulations on environmental and social impact assessment in Vietnam (Hanoi, Hai Phong, Thanh Hoa, Binh Thuan)

Client: Urban Upgrading Project Management Unit, Urban Development Agency, Ministry of Construction

Task: Support to prepare documents, printed, produce film for ending of project MDR – UUP (Provinces in the Mekong Delta)

Year: 2018

Client: Vietnam Union of Science and Technology Association (VUSTA)

Task: Assessment of current status of energy labeling regulation implementation for energy consumption equipment, instruments in Vietnam

Year: 2018

Client: Industrial Development Consultancy and Promotion Centre- Department of Industrial and Trade of Vietnam

Task: Study and establish norms of raw, fuel and energy consumption for 01 unit of the plastic industry

Year: 2018

Client: Hanwha Energy Corporation (“HEC”)

Year: 2018

Energy Efficiency Role

Energy plays an important role in the development of every nations, is the bloodline to feed the economic. However, the traditional energy source are depleting and the use of tradional fossil fuel is also cause negative impact to human and environment such as climate change, global warming. Natural phenomenons such as flood, drought, and coastal erosion have been occurred more and more often causing huge damage to the development of economic, social and living environment.

Vietnam is developing country; energy demand over years is quite high and will maintain in the following years, as expected, in 2014-2030 periods, energy demand of Vietnam will increase with an average rate of 5.9%.

Using energy efficiency and conservation is very important in the process of energy development and ensure energy security. Well-perform this work will contribute to meet the demand of using energy which increasing more and more of the national’s economic, also protecting the environment, rational exploitation of energy source helps saving foreign currency and develop economy-social sustainably.

Energy Efficiency and Conservation Policy in Vietnam

In the recent year, the Government has various guidelines and implemented policies to perform using energy efficiency and conservation, decreasing environment pollution and reducing production cost. Especially in 2006, the Government approved Vietnam National Energy Efficiency Program (VNEEP) about using energy efficiency and conservation from 2006-2015 in Decision No 1427/QĐ-TTg dated 2/10/2012; And, in 2010, the Congress approved “The Law on using Energy Efficiency and Conservation”.

VNEEP about using Energy Efficiency and Conservation (EEC) identified clearly target and specific solution to implement. Specific objective of the Program includes:

(i) Achieve saving 3-5% of total national energy consumption in phase 1 (2006 – 2010) and 5 – 8% in phase 2 (2011 – 2015) comparing to energy demand in accordance with electricity development plan in 2011 – 2020 period and consider to 2030.

(ii) Formation a network that enforces the energy-use efficiency and conservation law, implements energy efficiency and conservation program in the centre and local level, organize training course, certifies energy management certification for 2000 staffs in the industrial production fields.

(iii) Widely use of high-performance devices, gradually replacing under-performance equipments, proceeds to eliminate outdated technology. Apply modern standards and technology to improve energy performance in the production and business activities of enterprises, reach at least 10% energy intensity of energy-intensive industry such as: cement, steel, textile and apparel industry.

The Law on using Energy efficiency and conservation take effect in 2011. The law regulates the responsible of using ECC of industrial production site, in which, industrial production site is responsible to develop, implement energy-use efficiency and conservation schedule annually; integrate energy management program with other quality management program, clean production program, site environment protection program; Application of standard, technical procedure, energy use norm which were prescribed by state authority agency; seclect and apply modern production model and procedure, suitable technical solution and high-performance energy equipment; use of renewable energy which has higher performance in the production line; Apply technical measures, workshop architectural to maximum the use of natural lighting, ventilation and cooling; maximum use of natural lighting and ventilation; Implement operating procedure, maintenance mode, maintain facilities and equipment in the production line to prevent energy loss; Gradually eliminate outdated facilities, equipment, which consume lot of energy as stipulated by the Government.

For key designated energy using sites, are responsible to:

(i) Develop and implement yearly and five-years plan about using energy efficiency and conservation which is suitable for production and business plan; report to state authority agency at local result of using energy efficiency and conservation implementation;

(ii) Build liability regime for individual and group which related to the implementation of using energy efficiency and conservation plan;

(iii) Appoint energy manager;

(iv) Implement energy audit each three year;

(v) Apply energy management system;

(vi) Implement standard of using energy efficiency and conservation in new building, renovating and expanding of facility.

To implement the Program and the Law on using Energy Efficiency and Conservation, the Gorvenment, Ministries and Departments have enacted a lot of legal documents to guide and prescribe those contents and solutions. Specifically:

(i) Decree No.21/2011/NĐ-CP dated 29/3/2011 prescribed on the detail and implementation measure of the Law on EEC;

(ii) Decree No.74/2011/NĐ-CP dated 24/08/2011 prescribed on administrative sanctions for the use of EEC;

(iii) Decree No.1294-TTg dated 1/8/2011 published the list of designated energy using sites in 2011;

(iv) Circular No.09/2013/TT-BCT dated 20/4/2012 prescribed on planning of using EEC and energy audit implementation;

(v) Decision No.1427/QĐ-TTg dated 2/1/2012, the Government approved VNEEP on using EEC phase 2012 – 2015;

(vi) Decree No.134/2013/NĐ-CP: Prescribed on sactions in the field of electricity, hydro dam safety, using EEC;

(vii) Decision No.78 /2013/QĐ-TTg: Promulgating the list of energy consumption vehicles, equipment for disposal and ban on construction of low-efficiency power plants;

(viii) Decision No.1535/QĐ-TTg dated 28/8/2014 published the list of designated energy using sites in 2014;

(ix) Circular No.45/2014/TTLT-BCT-BTC-BKHĐT, Guide on managing and using state budget to implement VNEEP on using ECC in phase 2012 – 2015.

(x) Circular No.02/2014/TT-BCT dated 16/1/2014 “Provision on using EEC measure for industrial sectors”.

With the implementation of the Law on using Energy Efficiency and Conservation and projects within the framework of VNEEP about using EEC, Vietnam has gradually remove barriers and create condition to promote energy-use efficiency and conservation activities in the whole country… Estimation, in 2011-2015 period, energy saving in Vietnam reaches 6% of total national energy consumption, this is meaningful figure, because if there isn’t any savings, new electricity plants may have to be built in order to compensate power shortage.

Energy saving implementation challenges

In addition to these achievements, Vietnam is also facing many difficulties to promote energy-use efficiency and conservation sustainably. In particular, the dominant issue is the awareness of community and enterprise about using EEC which is still limited, not ready to approach information of technology and energy saving solutions; Enterprise does not have fund or cannot access to preferential credit loans for energy saving projects; Incentive mechanism for invested enterprise to replace outdated production line to high-performance technology line, energy saving has a lot of limitations, not really encourage business…

According to the current regulations and experiences of some foregin-fund projects about using EEC which have been implemented in Vietnam, to promote the implementation of energy saving measure, accompanied with mandatory policies for the compliance of enterprise, incentive mechanism is also use to encourage and support enterprise to implement provisions. However, incentives mechanisms to implement EEC solutions are expected by enterprise such as tax reduction or exemption, tax deduction for energy saving instruments… are currently not available. Concessional loans to enterprises to implement EEC solutions are also not having any guiding document.

Energy saving potentials

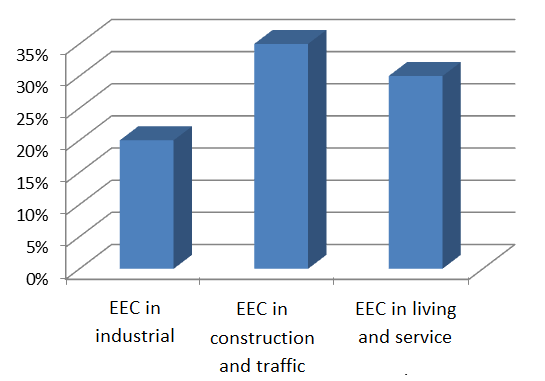

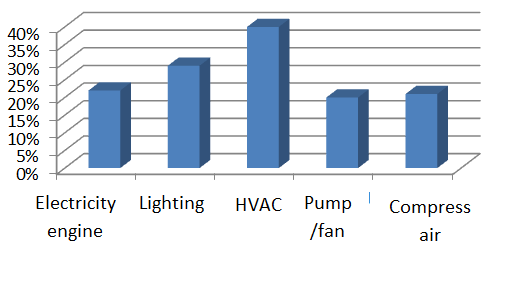

As expected, the potential of saving energy is high, sectors which have high potential of saing energy including service, construction, traffic, industrial production…

Energy saving potential according to sector

Vietnam industry currently has high energy intensity: To make 1000 USD the added value, 600-700 kg TOE have to be consumed. According to IEA, to make 1 USD of total GDP, Vietnam consumes 1.02 kWh electricity (or 0,463 kg TOE), nearly double than Korea, 3.5 times than France and nearly three times than the US. Vietnam is one of few countries which have energy intensity consumption increase

Vietnam industry currently has high energy intensity: To make 1000 USD the added value, 600-700 kg TOE have to be consumed. According to IEA, to make 1 USD of total GDP, Vietnam consumes 1.02 kWh electricity (or 0,463 kg TOE), nearly double than Korea, 3.5 times than France and nearly three times than the US. Vietnam is one of few countries which have energy intensity consumption increase

Recommendation from enterprise

The State should enact more guiding documents for measure implementation such as tax incentives. Currently, project investors cannot take full advantage of the benefit that tax incentive measures bring to them because tax authority agencies do not have guide to implement those measures.

What is EAP?

At the opening speech, Mr. Nguyen Dinh Hiep – Vice President, General Secretary of VECEA (Vietnam Energy Conservation and Energy Efficiency Association) said that EAP is the Eco-Action Program, that was originated from Japan. The Program is developed based on Ecological Action Guideline 21 (EA21). The EAP guides small and midsize enterprises towards efficient use of energy and minimizes greenhouse gas emissions

EAP can be understood as a form of Environmental Management System (EMS) that is built to suit small and medium enterprises in which cost savings are emphasized. Because of the small size of the business, EAP conducts very detailed and cost-effective solutions. With the goal of providing and disseminating the basic knowledge of EAP, promoting and replicating the EAP model nationwide, step by step change the awareness – building a sense of well-being, combining economic objectives and ecological targets in the production and business of enterprises.

In Japan, many large enterprises determine that an environmental management system is one of their basic conditions when entering into a transaction and also, they are required to have this condition when transacting. The import of goods also requires importing from enterprises having environmental management system. EA21 participating units will be evaluated and certified by the 3rd intermediary agency so that the prestige of the unit will be improved in the social aspect. The environmental reports of the unit will be published outside so the prestige of the unit will be enhanced for consumers.

How to strongly promote EAP?

According to Mr. Mai Van Huyen – Director of Green Development Center (GreenDC), EAP has been introduced and applied in Vietnam since 2013 within the framework of the Joint Credit Program (JCM). Three cities have implemented this model: Ho Chi Minh City, Da Nang, Hanoi. By 2014, the number of participants is up to nearly 50 enterprises. Typically, Legamex Corporation that participated in EAP has reduced 90% of CO2; 19% -78% of solid waste due to a series of solutions: Sorting garbage; Installing electricity meters to monitor power indicators of each unit; improvement of lighting system; use power saver for sewing machines and specialized machines; using high performance motors, insulating for glue pressor, insulating steam pipes for ironing machines; monitoring monthly fuel norms, regular engine maintenance

Implementation of EAP contributes to improve business credibility; Satisfying customer requirements; Comply with environmental legislation and especially easy to implement environmental management in small and medium enterprises at low cost.

Actually, last year, the number of enterprises interested and participated in EAP have increased. It can be seen that the awareness of the small-medium enterprises (SME) community about applying of EAP are increase, which means that the entering of EAP has increased in the SME community. The next good news is that VECEA and ECC Ho Chi Minh have been restarting EAP in major cities. That confirms the important role that EAP plays in this small business type.

However, in order to enhance EAP to the SME community, marketing and communication activities should be promoted to small and medium enterprises. Develop and recommend incentive mechanisms for small and medium enterprises to participate in the program. Create pilot demonstration models.

In the context of the limited implementation of the responsibility for environmental protection and rational use of natural resources by the SME community, the incentive to implement the EAP model in enterprises will have many benefits such as reduce greenhouse gas emissions, reduce water pollution, save costs …

Green Development Center.

Consultation Workshop on Climate Change Impacts and Adaptation Measures organized by the Department of Climate Change, Ministry of Natural Resources and Environment within the framework of Vietnam’s Third National Preparation for the United Nations Framework Convention on Climate Change (UNFCCC) was convened at the Hanoi Club Hotel on June 22, 2018.

The objective of the workshop is to ask for opinions of relevant agencies to evaluate impact of climate change to address a number of socio-economic issues and propose some adaptation measures for the development of Vietnam’s third national communication for UNFCCC.

Throughout the workshop, the reports were presented and highlighted areas affected by climate change, for example: impacts of climate change related to water resources, coastal areas, transportation, agriculture, forestry, fisheries, public health and gender; Presenters also proposed measures for adaptation to climate change.

The presentation emphasized that women are more likely to be vulnerable to the effects of climate change due to health factors, access to information and land ownership; pressure of work with the family; Limited participation in community decision-making processes…

Green Development Center.

On the morning of March 9, 2018, the second Project Steering Committee (PSC) “ Promoting the energy efficient industrial boilers, adoption and operating practices in Vietnam” was organized at HQ of Ministry of Industry and Trade in Hanoi.

PSC reported the implementation progress of the Project in 2017 and Action plan of 2018 as well as some problems which need to be consulted by members of PSC and feedback from.

There are 10 PSC members from related ministry/department who participated in the meeting such as: MOIT, MONRE, MOLISA, MOST; ECCs (Hanoi, Ho Chi Minh and Da Nang) and representative from United Nations Industrial Development Organization (UNIDO) in Vietnam and HQ.

By 2017, the project has been implemented for more than 10 years. With the efforts of PMU and close guidance of General Directorate of Energy (currently is Department of Energy Efficiency and Sustainable Development); many activities in the framework of the project has been implemented as below:

Overall, activities of the project have been implemented in line with the plan set out in 2017 and have achieved certain results. However, some activities of Component 2 & 3 are still in the process of being prepared (for example, the selection of enterprises participating in the demonstration project replacing the boiler, the process of collecting data of industrial enterprises …). The PMU also plans to accelerate the implementation of these activities in 2018.

After the presentation of the project implementation progress in 2017 and the work plan of 2018 by the representative of the PMU, members of the PSC had many comments and feedbacks for certain issues of the project. In conclusion, members of PSC evaluated the project being implemented in the right direction and at the same time make recommendations on some activities to focus and accelerate the implementation in 2018, details as follows:

On the morning of 19th January 2018 at Hanoi, on the framework of the Project “Promotion of energy efficiency industrial boiler adoption and operating practices in Vietnam”, sponsored by UNIDO and hosted by Ministry of Industry and Trade (MOIT), Project Management Unit (PMU) collaborated with Green Development Center (Green.DC) to organize Consultation Meeting on Industrial boiler database system in order to obtain feedbacks and comments for draft of boiler database system and initial survey result report.

The purpose of developing boiler database is to assist the assessment and consideration of appropriate industrial boiler regulation and standards; provide database about boiler in industrial sectors and help boiler manufacturer capture the boiler market situation domestically for future development strategies.

Database has been designed with many information layers, users can access data on frequency and relative comparison, it is suitable for not only the demand of state management units but also for researchers, boiler manufacturers and users. Specifically, the general information layers will present the total number of boiler, design capacity, boiler using sectors, total energy and fuel consumption annually… Detail information layer will show number and percentage of boiler according to boiler type, manufacturer, installation year, industrial sector, regions, origin, longevity, type of fuel…

Report at the Seminar, Consultant unit – Green.DC illustrates that there are nearly 1000 enterprises have been surveyed and collected information from nationwide. Some basic information can be accessed easily based on the first input information that was collected from surveyed enterprises, for example:

Speaking at the seminar, delegates said that, in the past year, in line with economic development, the production and adoption of boiler in industrial sector has been growth. However, there are no comprehensive statistic on the current status of boiler in the industrial sector in Vietnam, therefore, the development of industrial boiler database system is very important and necessary. Delegates also proposed that the survey must be continued to add more number of industrial enterprises using boiler in Vietnam, proceeding to develop a national database of industrial boiler.

According to the plan, the survey will be continuously implemented. Database will complete and officially put into use since August 2018.

Green Development Center.